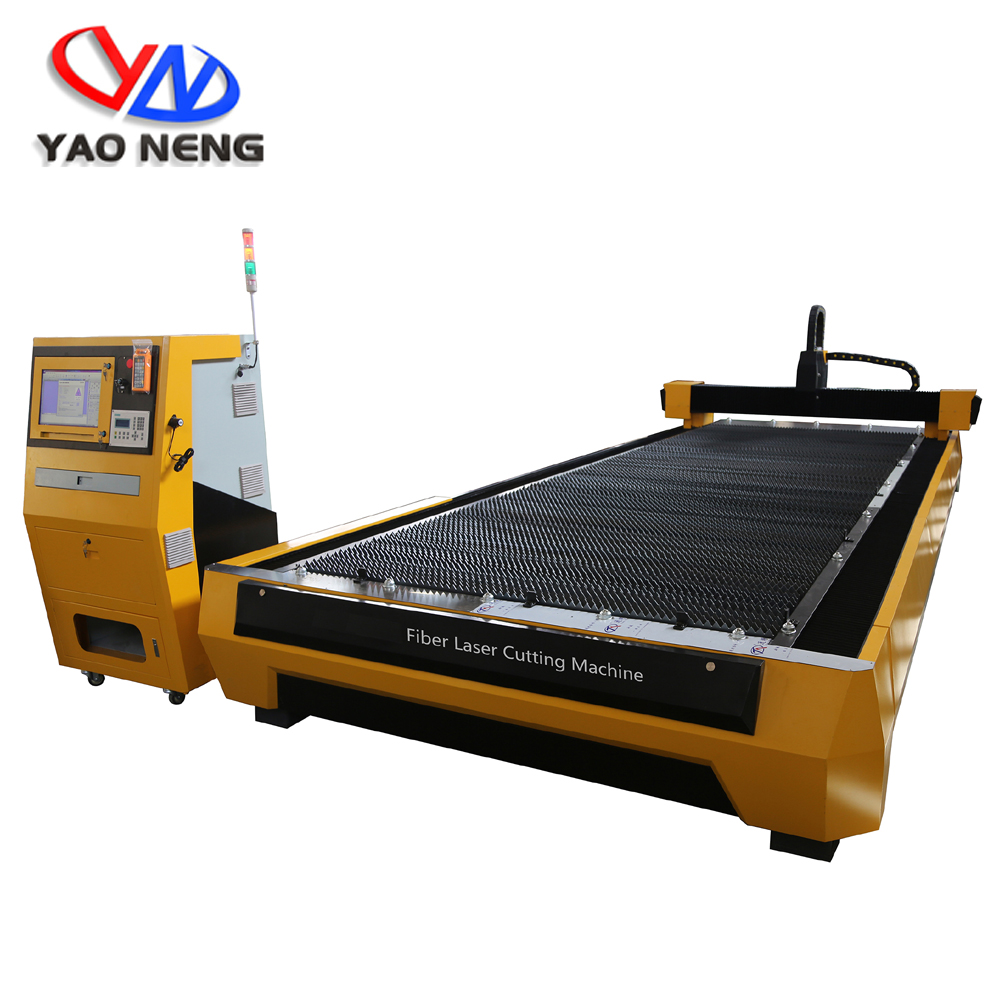

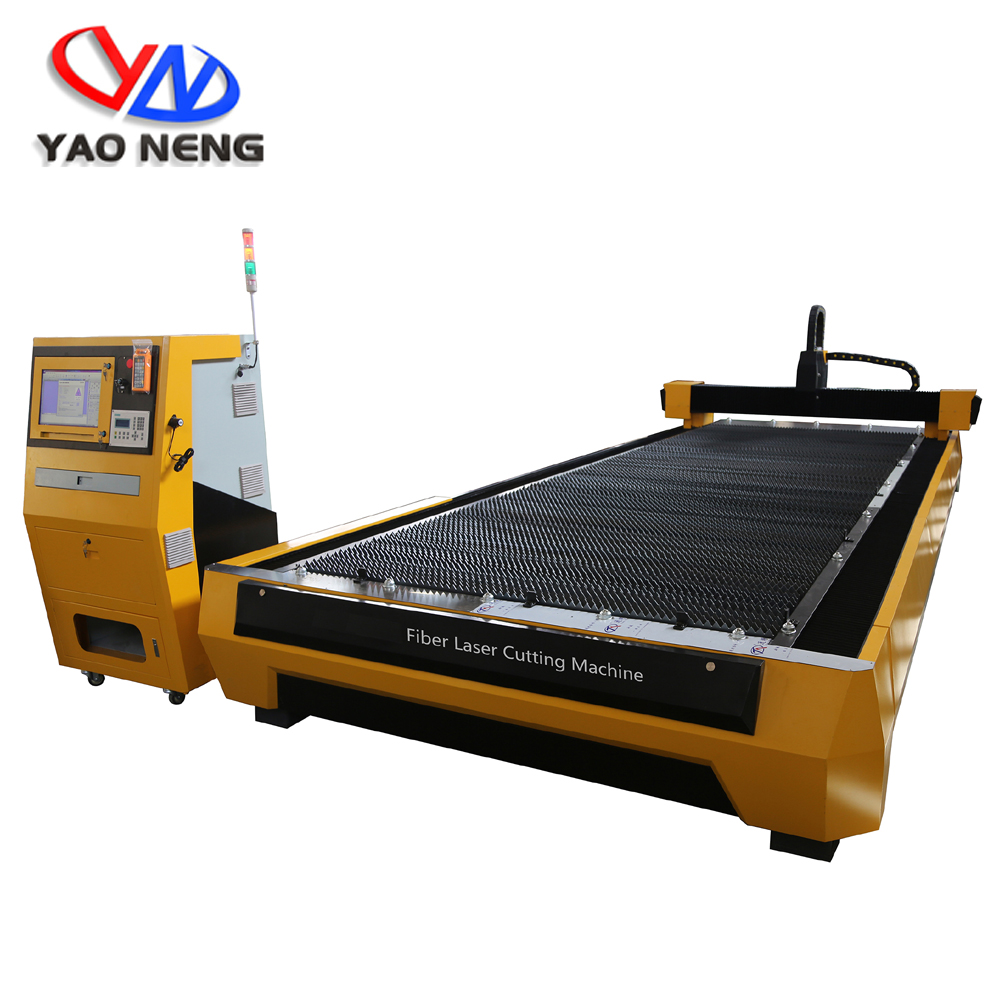

Professional design team, macro atmosphere, lathe bed adopts the seamless steel pipe welding, to deal with the stress when the tempering, fine processing, Taiwan straight line rail of silver, Germany high precision gear and rack, Henry AEPEX6 arc reducer, Taiwan 850 w yaskawa servo motor, low noise, stable transmission, high repeat positioning accuracy, can according to customer need to customize the cutting width and equipped with laser power, it is an ideal industrial laser cutting machine.

|

MODEL

|

YN-2060 |

|

WORKING AREA

|

2000X6000mm |

|

LASER POWER

|

300-2000w |

|

LASER WAVE LENGTH

|

1070nm±10nm |

|

WORKING MATERIAL |

MEDIUM THICKNESS METAL SHEET

|

|

CUTTING THICKNESS

|

0.2-16mm |

|

CUTTING SPEED

|

≤30m/min |

|

IDLE SPEED

|

≤60m/min |

|

CONSUMPTION POWER |

≤10kw |

POSITIONING ACCURACY

|

±0.05mm |

|

REPOSITION ACCURACY

|

±0.03mm/min |

|

COOLING METHOD

|

WATER COOLING |

|

VOLTAGE |

220V 50HZ, 1PH/380V 50HZ 3PH |

cut a variety of metal sheet, pipe material, mainly applicable to stainless steel, carbon steel, manganese steel,galvanized sheet, various alloy plates, rare metal materials such as quick cutting

![]()

![]()

It is widely used in sheet metal processing, aviation, aerospace, electronics, electric appliances, subway accessories, automobile,food machinery, textile machinery, engineering machinery, precision matching.

Parts, ships, metallurgical equipment, elevators, household appliances, process gifts, tools processing, decoration, advertising,metal processing, kitchen utensils processing and other manufacturing processing industry.