1.Import original packaging fiber laser, good bean quality, stable performance, without reflection lens and light path adjustment, maintenance free essentially, 100,000 hours working time

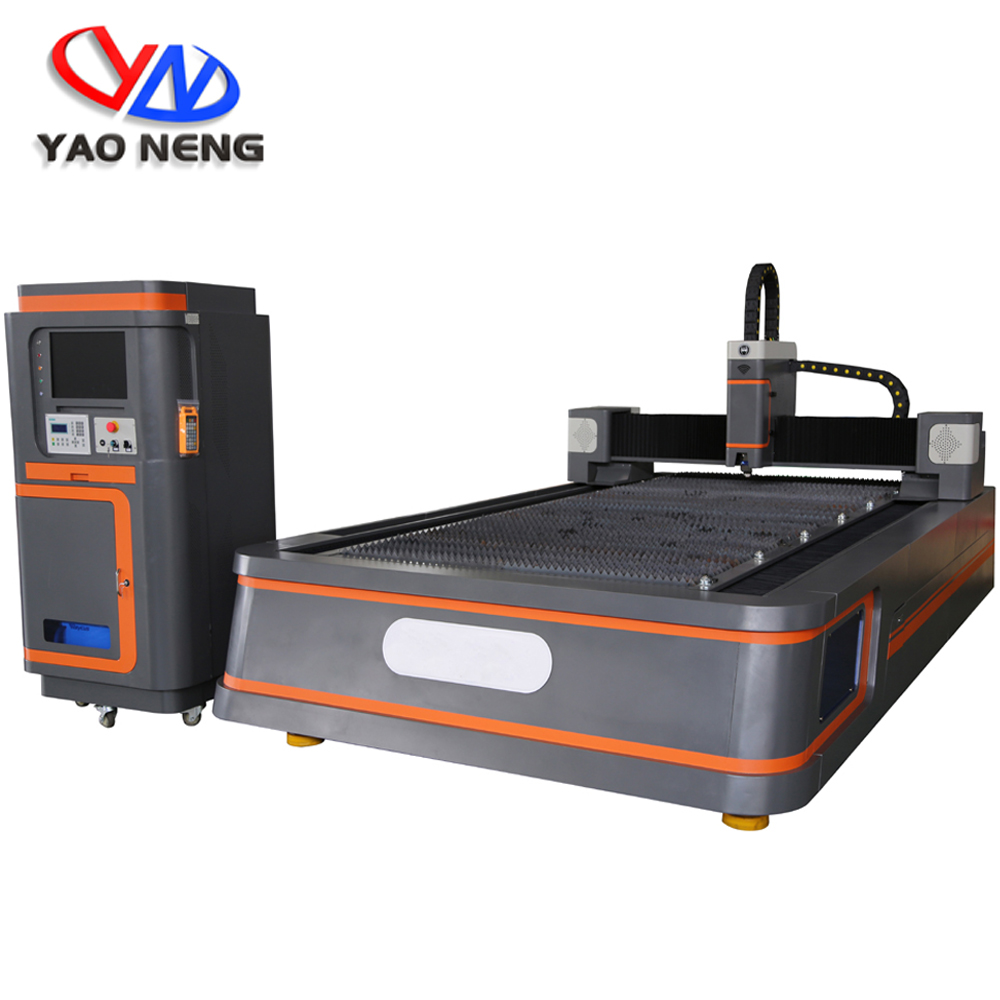

2. High rigidity machine bed, adopts exclusive standard annealing processing with high-temperature NC electric resistance furnace, ensure long-time stable precision of the machine tool

3. High transformation efficiency of fiber laser, which up to 30%, saving the working power consumption by a large margin, achieves low operating costs

4. Adopts the imported original guide transmission and servo motors, high precision, high speed

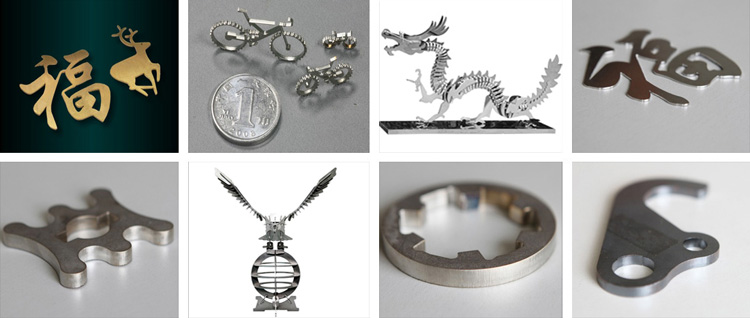

5. Smooth cutting edge, little deformation

6. Low power consumption, energy saving, overall power consumption 1/3-1/5 of the same power YAG machines, 3 times sheet metal cutting speed

7. Laser generated without gas, air can be used to cut sheet metal

|

MODEL |

RJ-3015A |

|

WORKING AREA |

1500X3000mm |

|

LASER POWER |

300-1000w |

|

LASER WAVE LENGTH |

1070nm±10nm |

|

WORKING MATERIAL |

MEDIUM THICKNESS METAL SHEET |

|

CUTTING THICKNESS |

0.2-10mm |

|

CUTTING SPEED |

≤30m/min |

|

IDLE SPEED |

≤60m/min |

|

CONSUMPTION POWER |

≤10kw |

|

POSITIONING ACCURACY |

±0.05mm |

|

REPOSITION ACCURACY |

±0.03mm/min |

|

COOLING METHOD |

WATER COOLING |

|

VOLTAGE |

220V 50HZ, 1PH/380V 50HZ 3PH |

Applicable for high-speed cutting on various metal plates such as S/S, carbon steel, galvanized sheet, electrolytic plate,aluminum plate, steel, brass, alloy plate, rare metals and other materials.

Widely used in the kitchen electric equipment, sheet metal chassis machine box, machine box equipment,electrical equipment, lighting hardware, advertising signs, auto parts, display equipment, all kinds of metal products, sheet metal cutting processing and other industries.