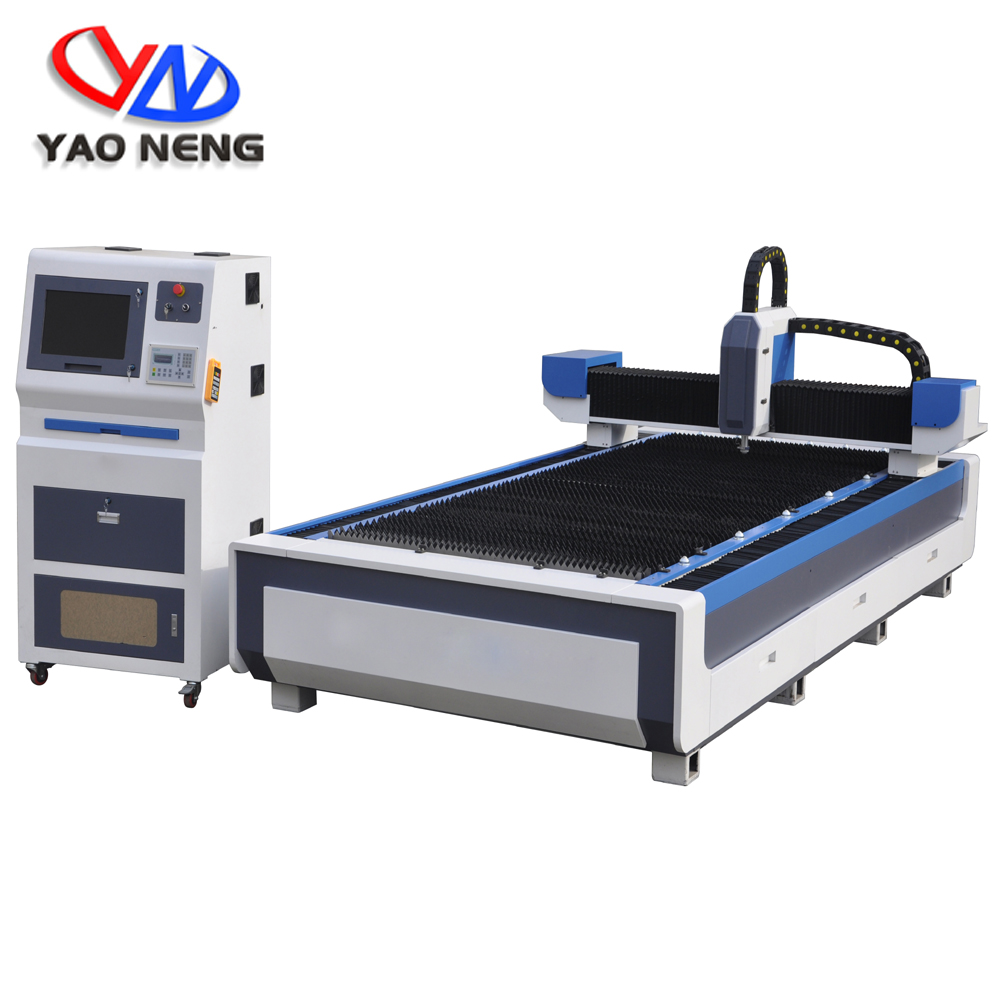

1. Moved crossbeam with imported high precision racks and linear guide rail, transmission stable, working with high precision.

2. Machine tool, crossbeam and worktable adopt integral welding structure, machine tool, crossbeam and worktable adopt integral welding structure, in accordance with the standard large machine, to stress annealing after precision finishing and then for vibration aging treatment, it can completely eliminate the welding stress and processing stress, keep high-strength, high precision, and also keep the 20 years of normal use don't deformation.

3. X, Y and Z axis use imported Japan servo motor, high precision, high speed, large torque and large inertia, performance is stable and durable, ensure the high speed operation of the whole machine.

4. Based on Windows operating system, use professional cypcut numerical control system for fiber laser cutting machine, integrated with laser cutting control special function module which is powerful with a good man-machine interface and easy to operate.

|

Machine Model |

RJ-1530A |

|

Working area |

1500X3000mm |

|

Laser power |

500-1500W(Optional) |

|

Laser wavelength |

1070nm±10nm |

|

Applicable materials |

sheet metal |

|

Cutting speed |

<=30m/min |

|

Travel speed |

<=60m/min |

|

Thickness |

0.2-10mm |

|

Positioning accuracy |

±0.05mm |

|

Repeat positioning accuracy |

±0.03mm/min |

|

Cooling model |

Water-cooling |

|

Weight |

3500kg |

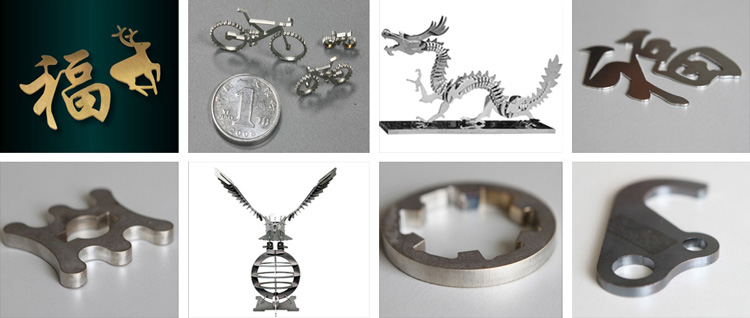

Professional for cutting a variety of sheet metal, has best quality to cut 0.5-6mm carbon steel, 0.5-5mm stainless steel, ( the max cutting thickness is 3mm if you use N2, and 5mm if you use O2) it also could cut galvanized sheet, electrolytic plate, siliciun steel and other metal materials.

Metal cutting, electrical switch manufacturing, elevator manufacturing, household electrical appliance manufacturing, cooking utensils, tools machining , such as a variety of machinery manufacturing and processing industry.