1. Mixing cutting capacity of the machine: for stainless steel, carbon steel, acrylic, and wood

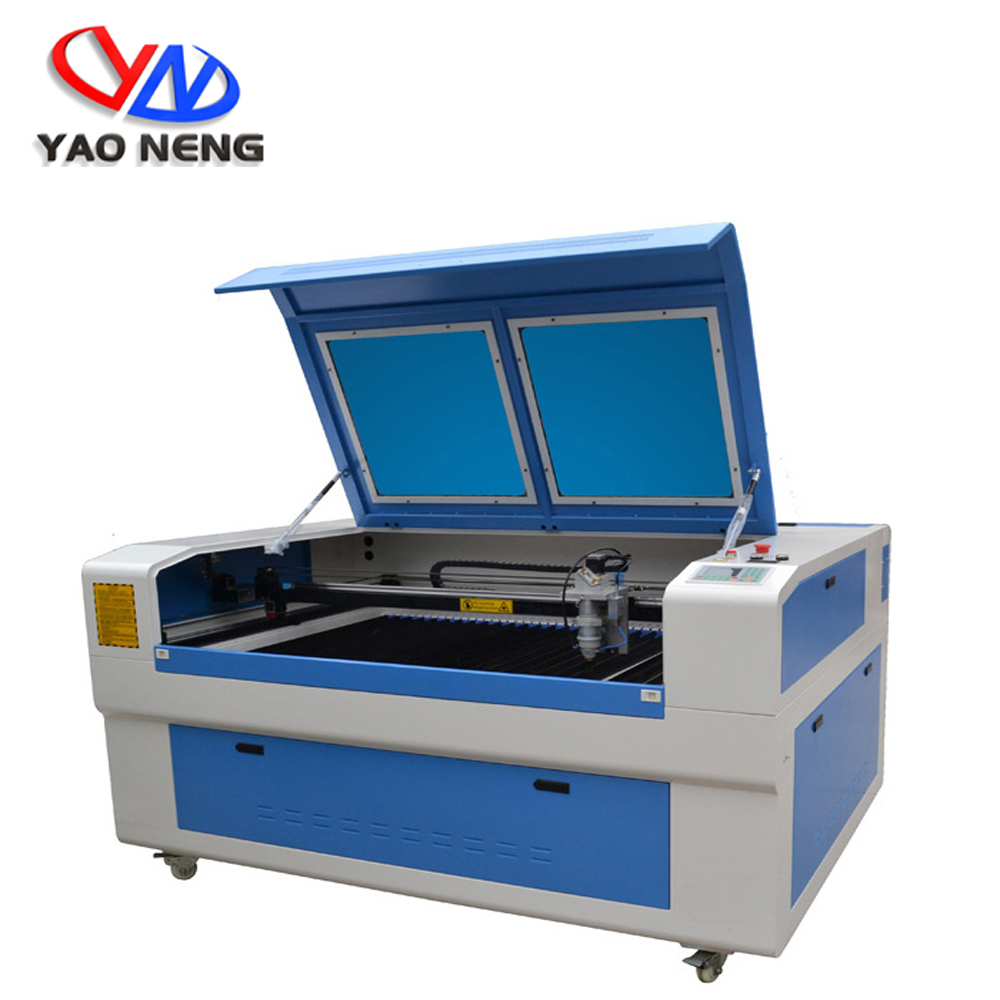

2. High-precision machine: X / Y use high accuracy motor and driver, with high-precision belt conveyor, greatly improve the response speed and precision cutting equipment, extend the life of the product.

3. Stability: optimized CNC control system can meet the precision machining parts, and stable dynamic performance, sustainable work long hours.

4. Good cutting section quality: mechanical cutting head system, the level of the cutting head with the follower plate, cutting position remains the same, the slit is smooth, no post-order processing section, to adapt to flat or curved sheet metal cutting.

5. The laser structure is simple, easy to operate, stable laser operation, low maintenance costs.

|

Power |

80-300w |

|

Cutting thickness |

0-30mm |

|

Supply Voltage |

AC 110v-220v±10% |

|

engraving speed |

0-6000cm/min |

|

cutting speed |

0-4000cm/min |

|

Positioning accuracy |

≤±0.05mm |

|

Operating humidity |

5%-95% |

|

Working temperature |

0-45° |

|

Working area |

1300*900 |

|

Packaging size |

1960*1480*1300 |

|

Data transmission interface |

USB |

|

Cooling mode |

Water-cooling and protection system |

|

Graphic file format |

PLT,DST,DXF,DWG,AI,LAS |

|

Net Weight |

300KG |

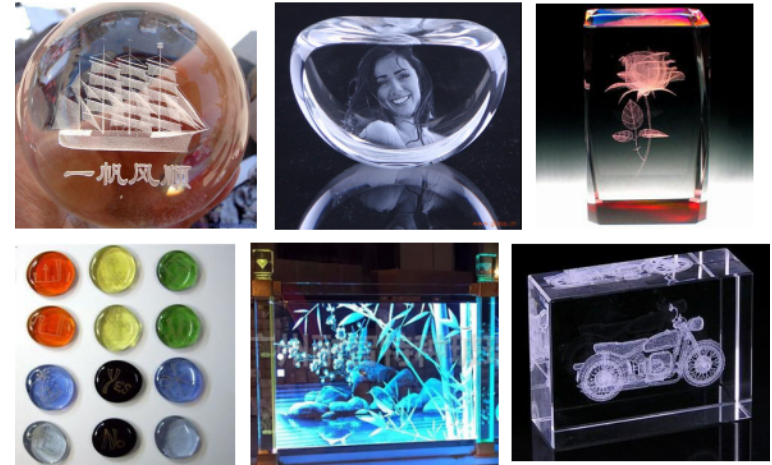

Laser engraving machine can work with most materials, such as Cloth, leather, wool, acrylic, plexiglass, board, plastic, rubber, crystal, ceramic tile, bamboo product, jade, granite, marble, resin and other non-metal materials.

Mainly used in the advertising industry (stainless steel and acrylic), sheet metal industry (steel), packaging (Die) and other cutting;

It can also working on non-metal materails cutting, such as: acrylic, wood, plywood, mdf and so on