1. Excellent Path Quality: Smaller laser dot and high work efficiency, high quality.

2. High Cutting Speed: cutting speed is 2-3 times than same power CO2 laser cutting machine.

3. Stable Running: adopt top world import fiber lasers, stable performance, key parts can reach 100,000 hours;

4. High Efficiency for photoelectric conversion: Compare with CO2 laser cutting machine, fiber laser cutting machine have three times photoelectric conversion efficiency.

5. Low Cost: Save energy and protect environment. Photoelectric conversion rate is up to 25-30%. Low electric power consumption, it is only about 20%-30% of traditional CO2 laser cutting machine.

6. Low Maintenance: fiber line transmission no need reflect lens, save maintenance cost;

7. Easy Operations: fiber line transmission, no adjustment of optical path.

|

Power |

80-300w |

|

Cutting thickness |

0-30mm |

|

Supply Voltage |

AC 110v-220v±10% |

|

engraving speed |

0-6000cm/min |

|

cutting speed |

0-4000cm/min |

|

Positioning accuracy |

≤±0.05mm |

|

Operating humidity |

5%-95% |

|

Working temperature |

0-45° |

|

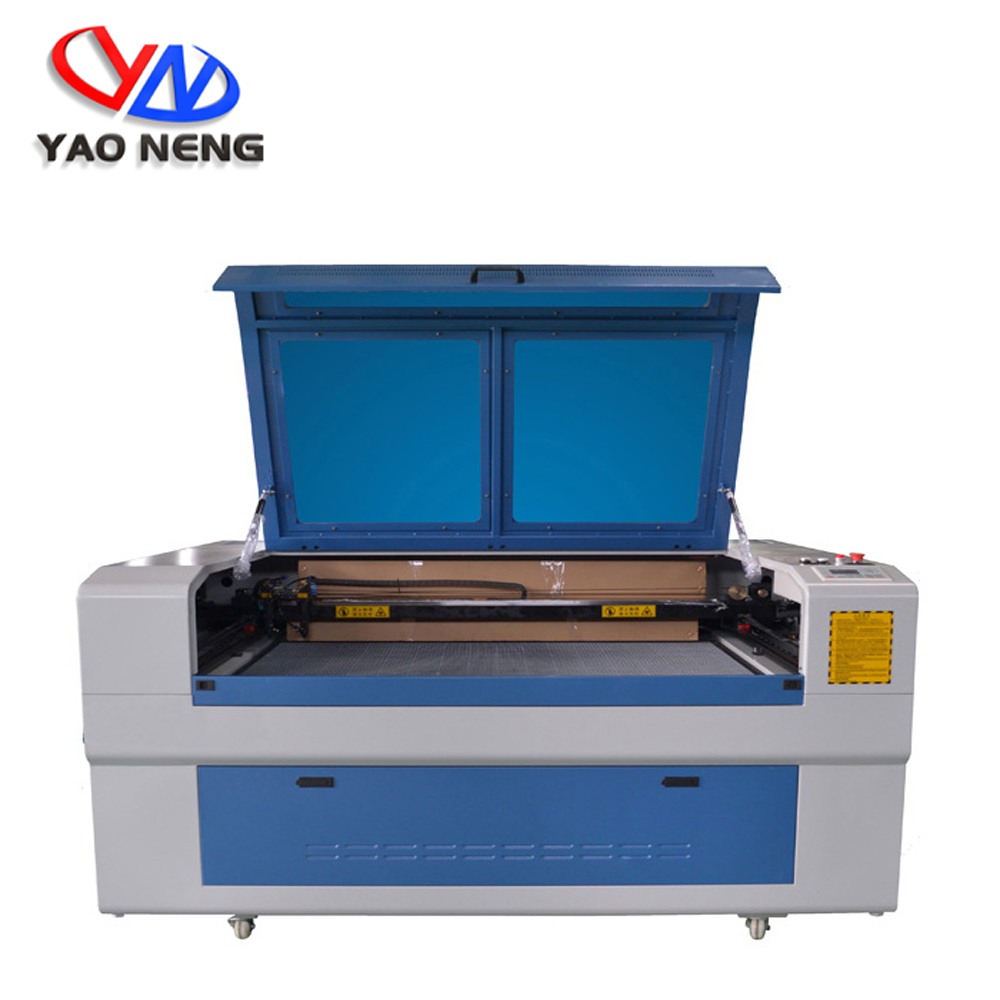

Working area |

1300*900 |

|

Packaging size |

1960*1480*1300 |

|

Data transmission interface |

USB |

|

Cooling mode |

Water-cooling and protection system |

|

Graphic file format |

PLT,DST,DXF,DWG,AI,LAS |

|

Net Weight |

300KG |

Laser engraving machine can work with most materials, such as Cloth, leather, wool, acrylic, plexiglass, board, plastic, rubber, crystal, ceramic tile, bamboo product, jade, granite, marble, resin and other non-metal materials.

Laser engraving machine is suitable for leather clothing, template cutting, printing and packaging, advertisement decoration, building decoration, computer embroidery tailoring, arts and crafts, paper products, plastic industry, acrylic board, decorative board, and other non metal sheet precision cutting and other industries